The CZC7EP series intelligent chargers incorporate a high-performance embedded charging control unit to regulate the charging current. Through parameter optimization in the main circuit module design, the chargers provide continuously adjustable charging currents catering to various lithium-ion batteries, thus addressing diverse charging process specifications.

The charging controller comes with pre-programmed default charging profiles, as well as a variety of BMS charging communication protocols. Additionally, the charging controller can be programmed and store customized charging profiles based on specific user requirements, thus fulfilling tailored charging process requirements upon delivery.

The charging controller constantly monitors a variety of parameters throughout the charging process, thereby equipping the chargers with a comprehensive suite of protective functionalities to ensure a smooth and secure ongoing charging operation.

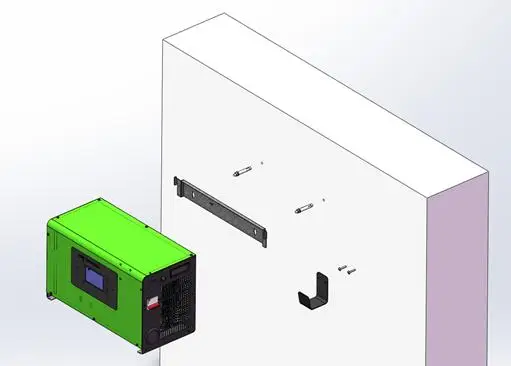

Instructions for Wall-mounted Installation

Begin by identifying the exact location for installation. Drill holes on the wall to fit M8 expansion screws, maintaining a hole spacing of 350 mm; mount the fixing bracket and the locking nuts, hang the charger, and select an appropriate position to install the cable hanger.

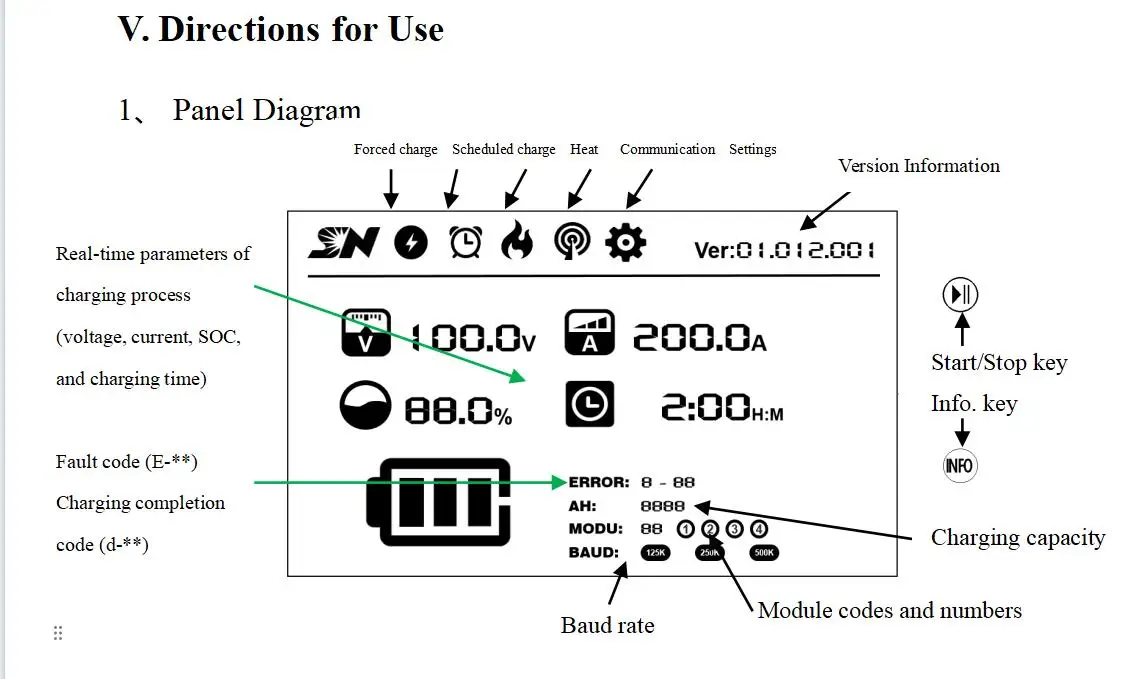

(a):人工控制模式——LCD屏上,可以人工控制启动充电、停止充电。

通讯控制模式——充电机与上位机连接,由上位机控制充电机(通过通讯来控制充电启停。按充电机的充电曲线进行充电。读取充电参数:充电电压、电流、充电时间、充电状态、警示信息等)。

(b): 充电机支持CAN通讯,能够与上位机连接进行数据传输。

(c) :人机界面:采用4.3”串口LCD彩色触摸屏,显示充 电过程参数;设置充电阶段各个参数。

(d) :充电数据记录:

在LCD屏上,检查充电过程事件记录。

EEPROM记录充电数据,可以进行记录数据分析。

SD卡记录充电过程曲线,通过PC机读取。(选配)

(e): 设置参数失电保护:对于用户设置的参数,系统可长久记忆,停电也不丢失。

(f): 保护功能:开路、接反、过流、过压、过热、电源缺相等的故障保护和警示功能。

(1):海拔高度不超过1000米;

(2):周围介质温度不高于+45℃及不低于-10℃;

(3):空气相对湿度不大于95%(当介质温度在20±5℃时);

(4):没有雨雪侵袭、无导电尘埃、无爆炸危险的环境;

(5): 不含有能腐蚀金属及破坏绝缘的气体、蒸汽的环境;

(6):充电机放置于通风良好环境,避免热量堆积,导致充电机散热异常;

(7):在垂直面倾斜不超过5度及无剧烈振动和冲击的地方。

(1):输入电源线的连接:

在充电机输入接线端子、接地端子上,分别连接电源输入线与黄绿双色的接地线;电源线输入导线截面积规格应符合技术参数表的要求。

(2):输出充电线的连接:

将两路充电导线分别接在充电机的两个正负输出端上。

连接时,注意充电机输出的“+”、“-”与蓄电池的极性一致!且保证连接应牢固可靠。充电输出导线截面积规格应符合技术参数表的要求。

(1):确认所用的电网电压是否与本机的额定输入电压一致。

(2):建议充电机电源输入导线直接与配电柜动力型空气开关连接,这个开关的额定电流应大于等于充电机输入电流的1.5~2倍。

(3):本机应放置在通风干燥的地方,避开高温、灰尘及腐蚀性气体。避免直接放置在阳光下与风吹雨淋。放置在室外时,需安装雨棚。

(4):为确保本机正常工作,要保持使用环境内的空气通畅。充电机周围30cm的空间,不得有妨碍通风的物体遮挡,并要经常检查充电机四周通风口是否堵塞。

.jpg)

Pre sales support 021-58222666/58228686

Sales Emergency 18918621852

After-sale service 4008883026、

021-58221666/58221622

Technical support 021-58228080、

13918674668

Emergency complaints 13901854050